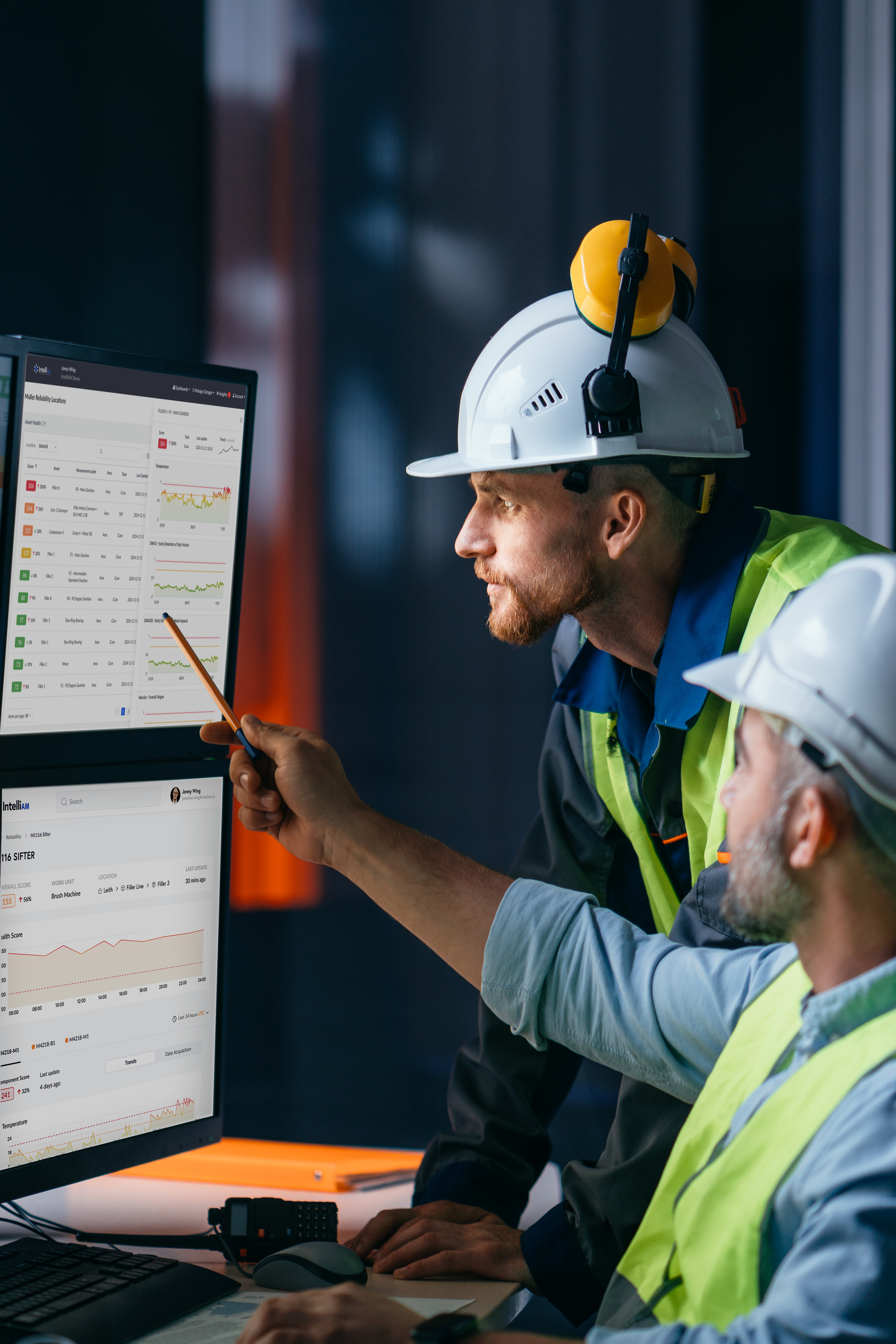

AI that unlocks a wealth of machine data to boost productivity and reduce operating costs.

Our pioneering machine learning platform uses AI to access billions of data points per month. At IntelliAM, building on the strong technical foundations and manufacturing expertise of 53North, our advanced algorithms analyse data in real-time to optimise asset performance and minimise downtime.

0114 299 5007

That depends - For predictive maintenance it is typical that Intelliam adds sensors such as vibration, stresswave, temperature and oil condition to your assets. However, productivity insights typically works with the data already available in your existing control systems, PLCs, historians, or SCADA platforms. In most cases, there's no need to add new sensors — we help you unlock the value of what you're already collecting.

We use Microsoft Azure’s enterprise-grade security. All data handled by Intelliam is secured using Azure’s built-in protections, including encryption at rest and in transit, identity and access management (IAM), role-based access control (RBAC), and continuous threat monitoring through Azure Security Center.

Securely and efficiently. Data is transmitted using lightweight, encrypted protocols that can be adapted to your network architecture — whether cloud-based, on-premise, or edge-connected. We support batching, filtering, and throttling to minimize bandwidth usage.

Our platform is guided by reliability and domain experts. We analyse your asset types and operations to identify the most relevant tags, signals, and data streams — prioritising high-impact sources that drive predictive insights and performance improvement.

We turn raw machine data into actionable intelligence. Intelliam provides early warning of potential failures, reveals hidden productivity losses, and identifies opportunities to optimise performance, helping you reduce downtime, cut costs, and improve reliability.

Yes. Intelliam supports a wide range of legacy and modern protocols (like OPC DA/UA, Modbus, and others), making it easy to integrate with older systems, even if they're decades old.

Absolutely. Intelliam can connect to your SQL-based data sources and ingest relevant historical or live data as part of your analytics pipeline

Registered in England & Wales

Company Number: 14992634

©2025 IntelliAm | Website Developed Fortay Media